The benefits of framing made from TRUECORE® steel

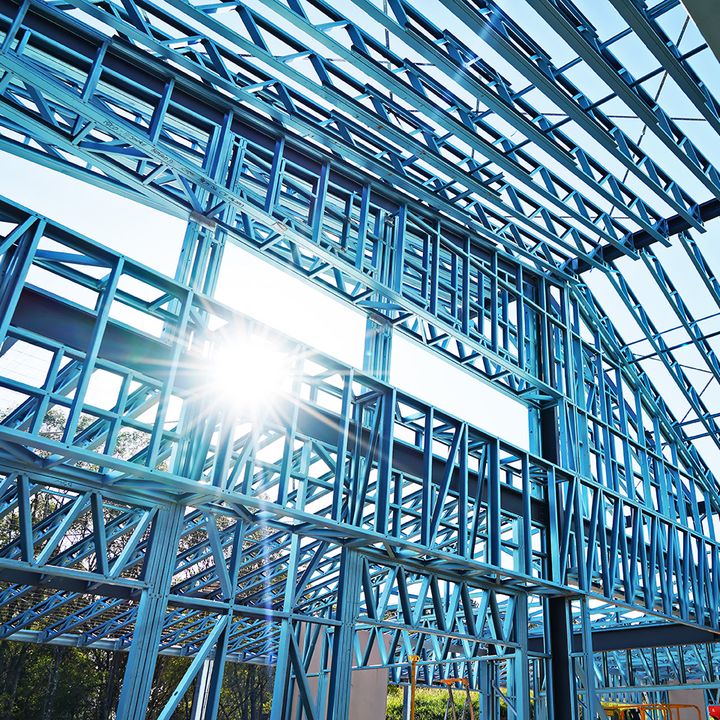

For applications where layout repetition is possible, the use of 3D modelling combined with modern construction methods can significantly speed up construction times.

Project collaboration right from the start

The construction process for framing made from TRUECORE® steel promotes close collaboration between builders, engineers and skilled fabricators right from the start, allowing for the seamless design, fabrication and installation of walls, trusses and bracing. Setting early expectations on design parameters and documentation can help minimise risks such as increased costs and delays.

Minimising construction risks in today’s economy

Installation of the prefabricated wall frames and trusses can be carried out with speed and efficiency because the structures are light and easy to manage on site. Offsite prefabrication requires reduced co-ordination of onsite trades and therefore reduced project time, helping to minimis risks such as escalating costs and delays.

TRUECORE® steel provides confidence

Using structural framing made from light gauge TRUECORE® steel provides sub-contractors and engineers with confidence. Test certificates can be provided for the steel almost immediately – giving engineers the confidence that locally sourced TRUECORE® steel will meet their specifications and require no further testing.

TRUECORE® steel helps meet growing education needs

“Framing made from TRUECORE® steel allows us to mitigate risk against termites and frame movement over time. We never see any bowing or warping in the light gauge steel walls.”

Building education facilities faster and more efficiently

Read the following case studies to find out how project teams are constructing education facilities with the help of framing made from TRUECORE® steel.

Technical resources and brochures

Explore our technical resources, brochures and case studies to learn more about TRUECORE® steel and how to get the most from it on your next project.