Some people have concerns that a steel framed home will rust. In reality TRUECORE® steel is specifically designed to deliver a high level of corrosion performance. Its advanced coatings provide long-lasting durability, backed by a 50-year residential warranty* in most situations.

About corrosion

‘Corrosion’ refers to the deterioration of a material because of electrochemical reactions with its environment. ‘Rust’ is a specific type of corrosion outcome. All environments are corrosive to some degree, and as a steel manufacturer, we take careful measures to minimise the risk of corrosion to our products.

TRUECORE® steel and corrosion resistance

TRUECORE® steel is a high-strength structural grade steel specifically designed for residential and commercial framing applications. Made by BlueScope at our Port Kembla NSW steelworks and further processed and coated at NSW and VIC facilities, it undergoes a number of steps to increase corrosion resistance and durability.

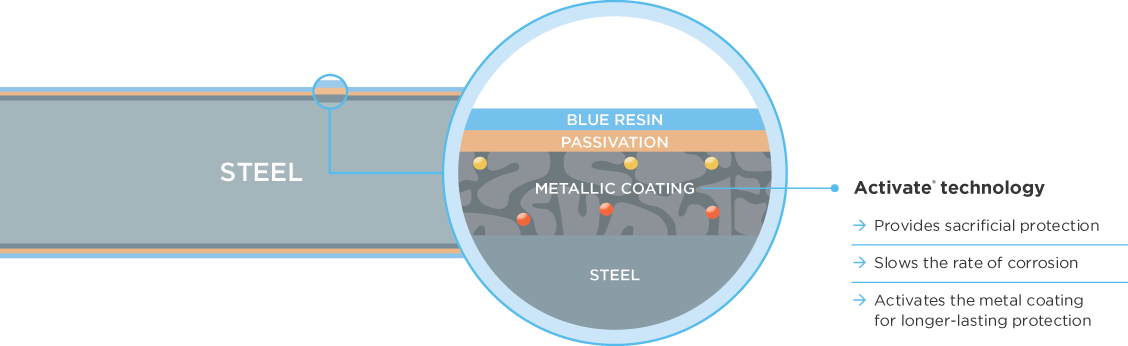

The steel strip is fed through a bath of molten metal, which results in the formation of BlueScope’s industry-leading metallic coating incorporating Activate® technology. When exposed to corrosive environments, this aluminium/zinc/magnesium (AM) alloy coating sacrifices itself to protect the steel substrate.

The coating has aluminium rich and zinc rich regions, with fine particles of magnesium compounds strategically positioned. Magnesium silicide (Mg2Si) is positioned at the bottom portion of the coating layer close to the base steel, and magnesium zinc (MgZn2) at the top portion of the coating layer. The magnesium silicide compounds ‘activate’ the metallic coating, resulting in more efficient and longer-lasting sacrificial protection. The fine structure of the coating also restricts corrosion pathways to the steel substrate.

To help further protect the steel, TRUECORE® steel is processed with a surface treatment known as passivation. Passivation provides additional short term corrosion protection for periods of storage and transport and initial exposure to the external environment.

In addition to the metallic coating process, we add a thin film of resin with the TRUECORE® steel distinctive blue tint, which helps protect the steel during frame manufacture and handling.

The overall outcome is a high level of corrosion performance and durability in most situations.

Warranty reassurance for peace of mind

BlueScope’s confidence in this corrosion performance is backed by our 50-year residential warranty* against corrosion to structural failure in most situations where the entire frame uses TRUECORE® steel. Full details including application and eligibility criteria, terms and conditions, are available at bluescopesteel.com.au/warranties.

Good building practices

While TRUECORE® steel is a robust frame material designed for durability, the performance of steel frames is further supported when good building practices are applied in design and installation.

Our Technical Bulletin TB-34 Steel Building Frames provides guidance on good practices for designers, builders and installers, as well as the key requirements for warranty eligibility.

Some key considerations to minimise the risk of corrosion include -

Isolating incompatible materials (eg dissimilar metals, including some fasteners, plumbing fixtures, magnesium oxide (MgO) based building boards & panels, and moisture-retaining materials)

Protecting the bottom plates of wall frames from ground moisture

Avoiding the introduction of excessive airborne salts into the building envelope

Marine influences are a factor that can affect the durability performance of a wide range of construction materials. Within our Technical Bulletin, we detail a number of construction measures that need to be taken to be eligible for a warranty that depend on the distance from marine and the type of marine environment.

Proven durability and corrosion resistance

TRUECORE® steel is specifically designed to resist rust and corrosion, with advanced coatings that deliver long-term durability.

There are many reasons to choose TRUECORE® steel as a house framing material. Along with our warranty, it is strong, durable, termite proof, won’t catch fire and won’t absorb moisture. All of these attributes help create homes that are designed for long life and resilience.

Further reading

For more information, refer to the following technical resources: