Steel framed homes can be thermally efficient, durable, and meet or exceed today’s energy efficiency requirements – such as 7 star NatHERS energy ratings - using mainstream construction practices.

Thermal bridging, where heat bypasses insulation through conductive materials like steel, is effectively managed with modern construction techniques such as installing thermal breaks, continuous insulation systems or indirect fixing of cladding using metal battens.

Learn how modern steel framing, trusted by major builders, supports comfortable, energy-efficient, and future-ready homes.

Steel framing and thermal performance

When it comes to building energy-efficient homes, thermal performance is crucial. It determines how well a home maintains a comfortable indoor temperature with minimal reliance on heating or cooling, directly impacting energy bills, comfort, and sustainability.

A common misconception is that steel framing, because it’s a conductive material, leads to poor thermal performance and that steel framed homes will overheat in summer and be cold in winter. But this oversimplifies how buildings perform and overlooks the many advantages of steel framing in modern construction.

The frame is just one part of the thermal puzzle

A home's thermal performance depends on many factors, including, insulation, airtightness, thermal mass, window type and size, overall design (including room and window layout, and building orientation), and quality of the detailing and construction.

The thermal envelope of a home includes the floor, walls, roof, windows, and insulation systems. In fact, the frame accounts for a relatively small portion of overall thermal performance.

Common weak points in a building’s thermal envelope often include:

Windows and window frames.

Gaps in insulation due to difficult to insulate areas or poor installation.

Air leakage through gaps caused by poor installation, poor building detail or building movement.

Thermal bridging

Thermal bridging occurs when heat travels through materials that are more conductive than insulation, such as steel.

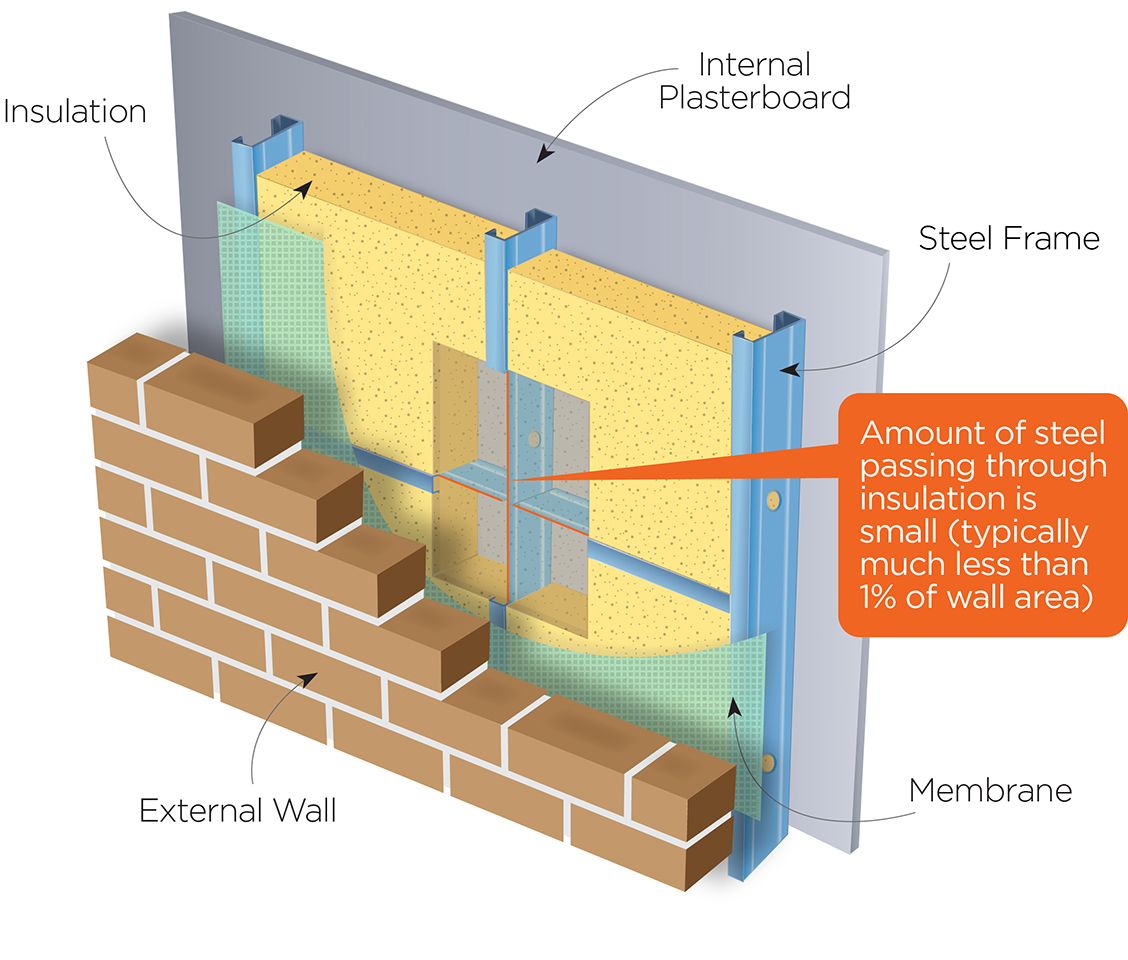

The steel used for residential framing is engineered for high strength and precision (typically less than 1mm thick and shaped into C sections), meaning the portion of the web of the frame that penetrates the insulation layer typically represents much less than 1% of the total wall (see figure 1). The amount of insulation and how it is installed is more important in effectively managing heat loss/gain and improving thermal performance of the building.

Figure 1 – Steel framing for homes is typically less than 1mm thick, with studs often spaced 600mm apart. This results in a small area for heat to transfer through the frame and therefore accounts for a relatively small portion of the overall thermal performance of a home.

Figure 1 – Steel framing for homes is typically less than 1mm thick, with studs often spaced 600mm apart. This results in a small area for heat to transfer through the frame and therefore accounts for a relatively small portion of the overall thermal performance of a home.

Thermal bridging is effectively mitigated by:

Installing thermal break materials between steel components and exterior cladding. Since 2006, thermal breaks have been a mandatory part of steel-framed construction where lightweight cladding is fixed directly to the frame.

Continuous insulation systems that wrap the building envelope i.e. insulation boards or reflective insulation¹.

Framing layouts that reduce direct contact from the outside cladding to the internal lining, such as indirect fixing using metal battens or using double studs.

The inherent cavity within brick veneer construction, can provide additional thermal resistance, which can be improved by using a reflective membrane¹.

As a result, in well-designed and code-compliant construction, the effect of a steel frame on overall thermal performance is limited.

Steel framed homes can meet (and exceed) thermal standards

Whether you're aiming for minimum compliance (7 star NatHERS energy rating) or higher, steel-framed homes can meet these goals using mainstream construction practices.

To match the thermal performance of a 7 star timber-framed home, simple, incremental steps can be taken, such as increasing ceiling insulation by R0.5 or using a reflective membrane for external walls. These are mainstream, cost-effective solutions that builders already use.

For those targeting higher levels of thermal performance additional measures – such as continuous external wall insulation, high-performance windows, airtight construction detailing and quality installation – can be employed, alongside overall design considerations like the home’s orientation.

Precision, stability, and airtightness

Steel frames have high dimensional accuracy and stability. They won’t shrink, warp or twist over time as there is no absorption or drying of moisture. These attributes can help create and maintain a tight building envelope, which in turn can help minimise air leakage and improve thermal performance.

Durability

Beyond thermal performance, steel framing won’t catch fire, won’t rot, and is 100% termite and borer proof, which supports the overall durability of the building.

Steel framing is a smart choice for energy-efficient homes

Steel-framed homes offer many advantages for builders and homeowners alike. This is increasingly recognised, with a number of major home builders across Australia now offering TRUECORE® steel as standard in all or some of their popular designs. With proper detailing and insulation, steel-framed homes can be thermally efficient and meet or exceed today’s energy standards. If you're building or renovating, don’t let outdated myths steer you away from steel. It’s a future-ready and durable material that supports high-performing and comfortable homes.

For further information go to: https://nash.asn.au/energy-efficiency-in-steel-framed-buildings/

¹ Ensure the product you are using meets relevant National Construction Code requirements for your climate zone, such as vapour permeability. Note that reflective membranes are available across all classes of vapour permeability.