It is a myth that steel framing, because it is thermally conductive, is the primary cause of condensation and mould issues in modern compliant Australian homes.

Thermal bridging of steel framing through batt insulation is effectively reduced through mitigation measures such as:

Battening out lightweight claddings;

Using reflective insulation wraps or

Installing thermal breaks.

These practices are typical ways of achieving National Construction Code (NCC) compliance and address potential issues related to ‘cold spots’ on internal linings – areas sometimes mistakenly assumed to be the highest risk for condensation and mould.

Furthermore, research¹ commissioned by the Australian Building Code Board (ABCB) found that any thermal bridging that does occur with compliant steel framing does not typically increase the condensation and mould risk of steel framed homes. Also, unlike organic building materials, steel does not absorb moisture or provide nutrients for mould growth.

Steel framing brings many practical advantages: it is strong, durable, termite proof, won’t catch fire and won’t absorb moisture. These attributes help create homes designed for long life, resilience and peace of mind. Myths and misinformation shouldn’t stop homeowners and builders from reaping the benefits of this contemporary construction method.

What is condensation and where is it most likely to occur?

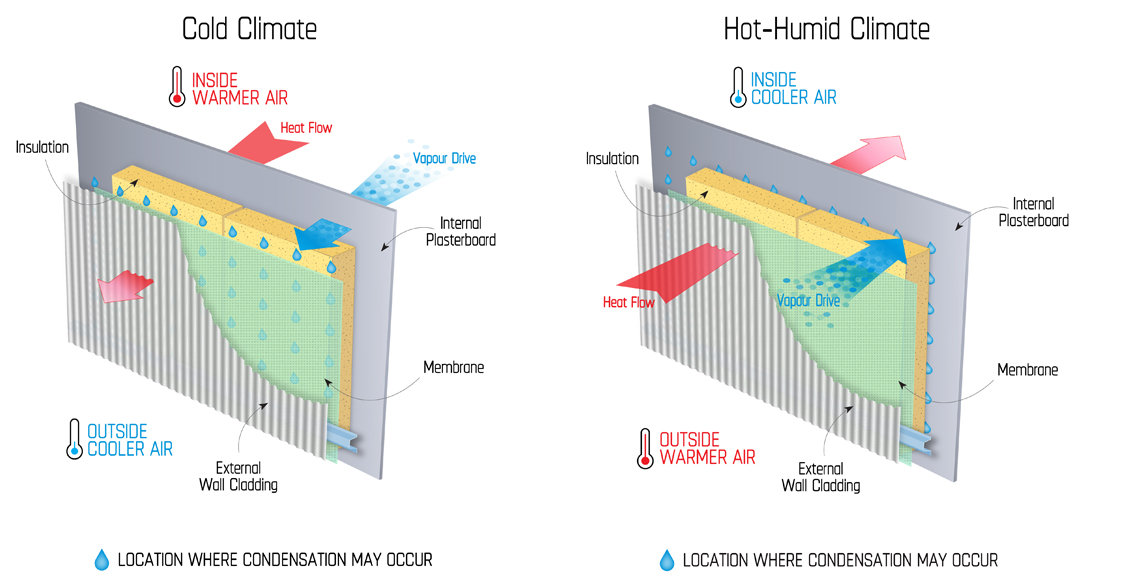

Condensation and mould risk for Australian homes is typically highest in cold climates (i.e. Climate Zones 7 and 8) and hot-humid areas (i.e. Climate Zone 1). These conditions can create potential for condensation and sustained moisture levels that can lead to mould growth.

Condensation occurs when warm, moist air meets a surface that is cold enough to drop the air temperature below its dew point. As explained in the next section, in code-compliant construction, the choice of framing material has less effect on the location of any condensation and mould than internal and external conditions.

In wall assemblies, condensation is most likely to occur on the cold side of the insulation layer, where moisture can condense on cooler surfaces if it is not properly managed.

As shown in Figure 1 (below), in cold climates, condensation typically occurs at the internal facing surface of the wall membrane. This happens when moisture from the warmer indoors migrates outward and contacts the cooler surface of the wall membrane.

Figure 2 (below) shows that in hot, humid climates, the reverse can happen. Moisture can infiltrate inward and condense on cooler internal surfaces such as the outdoor facing side of plasterboard. This is more likely when air conditioning is used to cool the indoor space.

Figures 1 and 2

The location where condensation is most likely to occur depends less on the framing material and more on internal and external conditions. Note that while the diagrams above show two climate extremes, many homes experience different combinations of these conditions depending on factors such as time of day, weather and use of air conditioning.

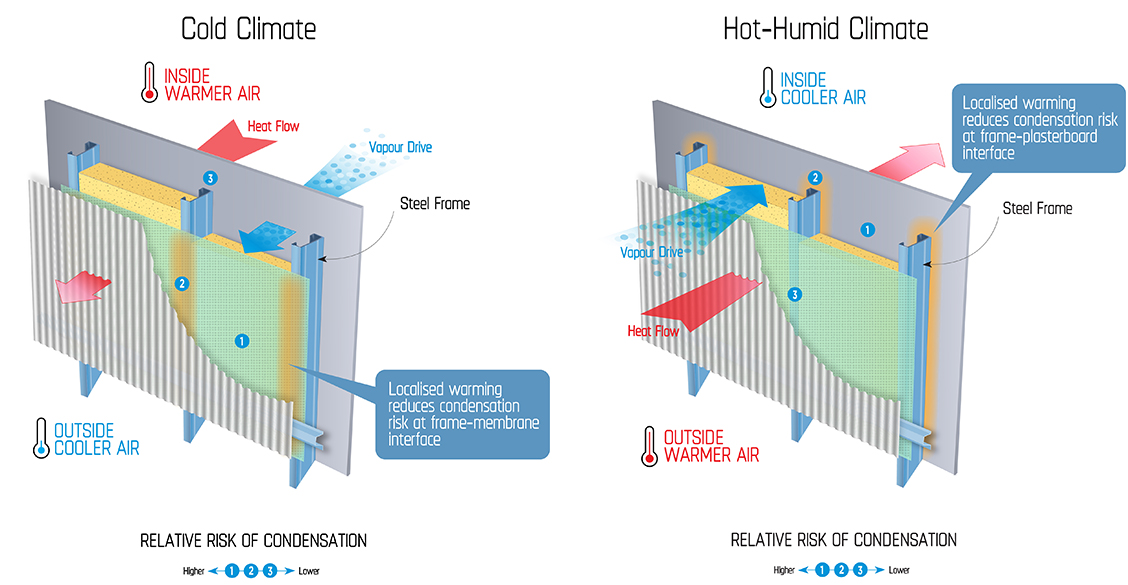

Steel framing does not typically increase condensation and mould risk

Heat transfer through steel framing helps to warm the cold side of a wall assembly, where condensation is typically most likely to occur. This localised warming effect lowers the relative humidity, thereby actually reducing condensation and mould risk at this location (ie location 2 in Figures 3a & 3b). The assumption that in cold climates the plasterboard adjacent to the frame (ie location 3 in Figure 3a) is where issues are most likely (as framing can slightly reduce temperatures here) is not supported by the research commissioned by the ABCB1 that found no mould risk at this location for the simulated cases2.

Condensation and mould issues on internal linings are typically a result of poor moisture management, leading to excessively high levels of humidity inside a building. The risk of high levels of internal humidity are now substantially reduced through NCC measures introduced in 2019 and 2022 requiring exhausts in bathrooms, kitchens and laundries to discharge outdoors, appropriate ventilation, and appropriate permeability of wall membranes.

In very cold climates (such as alpine regions), external insulation can be used to ensure internal plasterboard temperatures remain warm enough to avoid any potential issues with mould, condensation or patterned staining3.

For most Australian climates and typical indoor conditions, the ABCB’s research showed that condensation and mould risk is highest at the internal facing surface of the wall membrane in cold climates, and the outdoor facing side of plasterboard in warm climates.

Both locations are away from the frame (i.e. between the studs) and so framing does not increase the risk at this location.

Figure 3 (a & b) - A visual representation of the impact of framing on condensation and mould risk. Localised warming effects reduce local relative humidity at the highest risk location in the wall, for both cold and hot-humid climates.

Steel framing does not typically increase condensation and mould risk. Proper moisture management in the building is the most important factor to keep risks low.

Three principles to guide good practice across all construction types are:

Keep moisture out of the building (e.g. weatherproofing, use of vapour barriers in hot-humid climates where NCC requirements allow);

Allow any moisture that enters to escape (e.g. appropriate ventilation and exhaust systems, vapour permeability of wall membranes as per NCC requirements etc);

Take measures to minimise the risk of condensate forming (e.g. ‘blanket and foil’ type products under roofs in cold climates).

In addition, good detailing and installation is essential to ensure a home performs the way it was designed. When these practices are followed, condensation and mould risks are significantly reduced, regardless of framing materials and construction types.

Steel does not absorb moisture

In addition to steel framing not increasing condensation risk, the inorganic nature of steel makes it naturally resistant to mould and mildew. It does not absorb moisture or contain the nutrients needed for biological growth, thereby contributing to long term structural integrity. Additionally, as there is no absorption or drying of moisture, steel framing won’t shrink, warp or twist, which can reduce maintenance issues over time.

Steel framing is a smart choice

Supported by research and proven in practice, steel frames made from TRUECORE® steel provide builders and homeowners with peace of mind and lasting performance. They are strong, durable, termite proof, won’t catch fire and won’t absorb moisture - all helping to create homes designed for long life and resilience.

By focusing on facts rather than myths or misinformation, builders and homeowners can be confident that in code-compliant builds, steel framing does not typically increase the risk of condensation or mould, and can enjoy the many long term benefits that steel framing offers.

Further reading

For more information, refer to the following resources:

Condensation mitigation modelling: Final report by the Sustainable Buildings Research Centre (SBRC) for the Australian Building Codes Board (ABCB).

1 See Condensation Mitigation Modelling: Final Report completed by the Sustainable Buildings Research Centre (SBRC) for the Australian Building Codes Board (ABCB), which formed the technical basis for the NCC 2025 condensation provisions.

2 Lightweight battened-out and brick veneer walls were modelled in both warm (Climate Zone 1) and cold (Climate Zone 7) climates. Simulations were conducted in accordance with AIRAH DA07.

3 The risk of localised aesthetic issues such as patterned staining (“ghosting”) has been significantly reduced in modern construction, for more information refer to our page Code-compliant steel framing addresses ghosting.