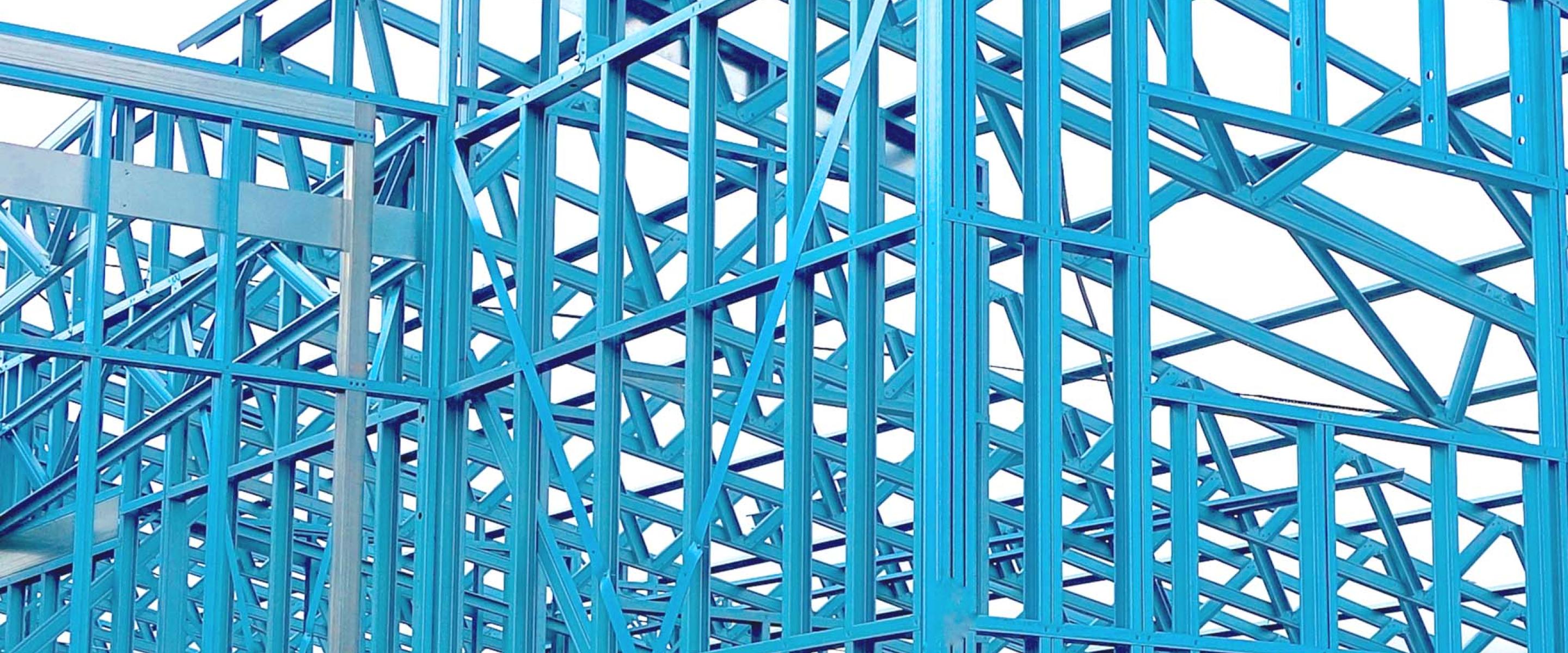

Smartsteel Frames

Promoting steel framing in WA

WA-based Smartsteel Frames is not only focussed on product expansion within the steel framing market - they are also promoting steel framing to broader audiences in their home state.

“Cost savings is where our clients really reap the benefits - the ability to speed up construction time with prefabrication can make a world of difference, not to mention the speed in which follow-on trades can be brought in.”

Summary

WA based Smartsteel Frames has been in the steel manufacturing business for many years. The company is founded on the principle of “do it right the first time” and they are particularly proud of feedback about how stress free, simple and accurate the framing, delivery and installation process can be for their customers. Client Relations and Sales Executive, Georgette Nicoski, says “We are keenly aware that time and economic factors are extremely important to our clients and we give them the due diligence they deserve to help bring time and cost savings to their projects.”

Smartsteel Frames combines their industry experience with a culture of attention to detail in their efforts to ensure their clients receive a quality product the first time, something that TRUECORE® steel helps them to achieve.

“TRUECORE® steel is dimensionally accurate and has allowed Smartsteel Frames to design a simple, fast and reliable framing system that requires little or no on-site rectifications”.

Georgette Nicoski, Client Relations and Sales Executive, Smartsteel Frames

Ms Nicoski continues, “And cost savings is where our clients really reap the benefits - the ability to speed up construction time with prefabrication can make a world of difference, not to mention the speed in which follow on trades can be brought in.”

This sentiment is echoed by Dean Pasene of KYDE Quality Builders, who has been working with Smartsteel Frames for several years. He explained that the key difference when using steel stud framing versus traditional timber framing or brickwork is, “It stays true and straight and requires very little, if any, adjustment at all upon completion to attain straight, plumb and level lines”.

Western Australia

TRUECORE® steel

December 2018