Hytek Framing - Redland Bay State School

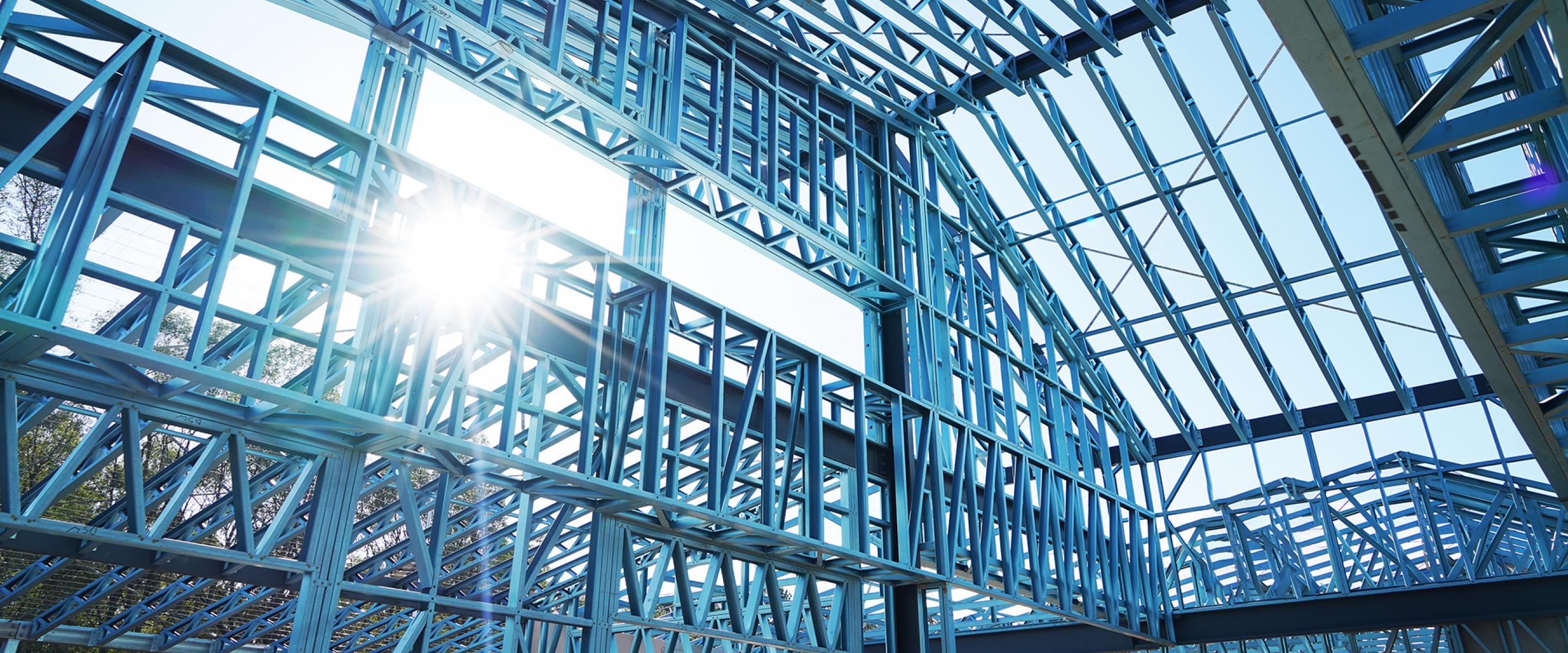

Framing made from TRUECORE® steel helps minimise the risk of escalating build costs in a new Queensland school.

Lightweight and strong, light gauge steel (LGS) framing made from TRUECORE® steel is designed and prefabricated off site, requiring early collaboration between builder, engineer and fabricator.

“I’ve been a carpenter for 35 years and spent the last 15 years working with steel framing. I’ve learnt it comes down to being up front and delivering what you say you’re going to deliver. TRUECORE® steel helps us do that” - Lee Jones, General Manager Hytek Framing.

Located on Serpentine Creek Road, the Redland Bay State School is scheduled to open at the beginning of 2024. The school will cater for students from prep to year 6 and will help educate young families from the new Shoreline development, which will be home to approximately 10,000 people.

Key Benefits Delivered

By utilising LGS made from TRUECORE® steel for the walls, trusses and bracing, the project realised the following benefits:

Collaboration from the start

Working closely with builder ADCO and Inertia Engineering, Hytek Framing designed, fabricated and then installed the LGS walls, trusses and bracing. Setting early expectations on design parameters and documentation helped ADCO minimise project risks (e.g. increased costs, delays).

Minimising risks in construction in today’s economy

After the completion of the slabs, builder ADCO handed over the erection of wall frames and trusses to Hytek Framing, using their own install teams. “For the building designs on this project, compared to structural steel, LGS framing made from TRUECORE® steel saved a full week and reduced trade co-ordination, which helped to minimise the risk of escalating costs and delays,” said Andrew Park, Senior Project Manager at ADCO Constructions.

TRUECORE® steel provides confidence

Using LGS framing made from TRUECORE® steel provides both sub-contractors and engineers with confidence. Test certificates could be provided for the steel almost immediately – giving the engineers the confidence that locally sourced TRUECORE® steel would meet their specifications and require no further testing.

Project highlights

The new Redland Bay State School is scheduled to open at the beginning of 2024 and will cater for prep to year 6. The new school was deemed essential to help educate school children primarily living within the new Shoreline Development, which will be home to approximately 10,000 people in growing families. Redland Bay State School will provide enrolment relief to surrounding schools within the new catchment area.

140,000 lineal metres of LGS made from TRUECORE® steel

Aaron Ng, Primal Agency

350-372 Serpentine Creek Road, Redland Bay, Qld

December 2023